BRIEF OF MACHINE

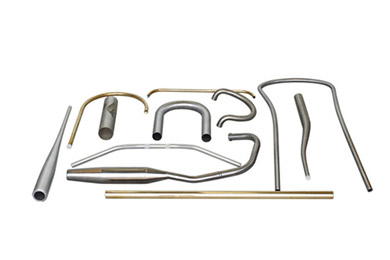

1 Pro-100 automatic tube finishing machine is high efficiency machine, it’s a best solution

for grinding & polishing & even mirror finishing the straight & curve round tube, even the oval tube.

2 Perfect for tube material: stainless steel, non ferrous metals, aluminum, brass, copper &etc.

3 The advanced planetary running system is a best polishing structure for best finishing quality & efficiency.

4 Use the different kinds of abrasive belts enables client to have a good idea for the wide range and different surface purpose.

5 Special automatic feeding system increases the productivity and quality in straight tubes. The planetary running system has the variable speed control to suit for different polishing requirement.

6 Advanced abrasive belts & feeding speed inverters supplies the wide range of power force.

7 Advanced electromagnetism lock & unlock function supplies the easy-setting of polishing diameter and abrasive belts replacement.

8 Advanced abrasive belts opening scheme system can let the tube easily come into polishing area.

9 Foot pedal control the planetary disc lock-unlock & abrasive belts opening

10 Pro-100 has a magnetic safety switch for planetary disc cover open-close

11 Pro-100 has got a dust exit connector to make the connection to a dust extracting system. (Optional buy).we recommends the use of dust extraction system, the use of an extraction system is extremely important, not only to reduce the dust of the working area, but also to increase the lifetime of the machine and its components.

TECHNICAL DATA

Main Technical parameter

|

Unit

|

Data

|

Polishing working capacity

|

mm

|

Ф10-114

|

Power of motors

|

KW

|

4.74

|

Machine consumption

|

A

|

10

|

Linear speed limits of feeding units

|

m/min

|

1-5

|

Linear speed limits of abrasive belts

|

m/s

|

8-25

|

Abrasive belts dimensions

|

mm

|

940 * 50

|

Voltage & frequency

|

/

|

380-400v,50Hz,Three Phase

|

Weight

|

kg

|

250

|

Overall dimensions

|

mm

|

1000 * 800 * 1300

|